Today, we want to retrace our history through the key moments in time illustrating our company’s ability to create, innovate and grow, while remaining committed to social responsibility.

The history of the group is a story of success in its fourth generation, in which the development of a multinational company perfectly combines with the past, present and future.

Today, we want to retrace our history through the key moments in time illustrating our company’s ability to create, innovate and grow, while remaining committed to social responsibility.

We have to go back to 1912 to discover the true roots of the company.

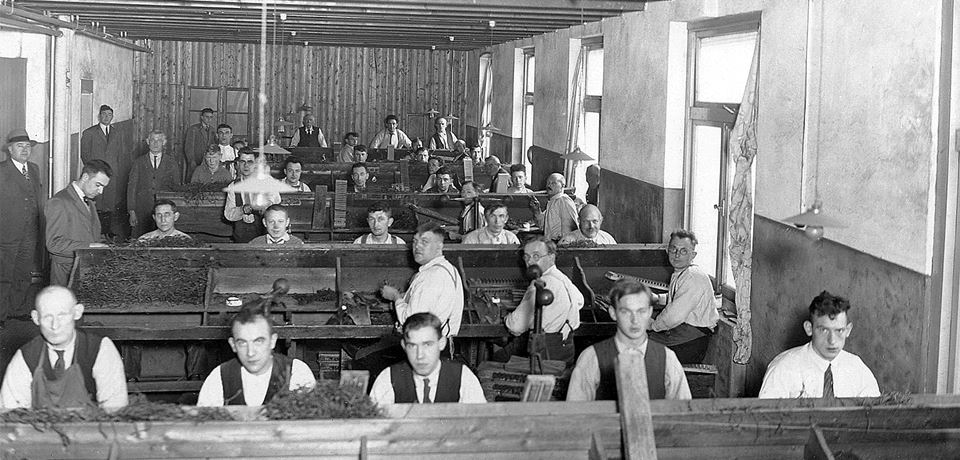

1912, is the year Hendrikus van der Sluis sees a business opportunity and buys his own cigar factory. With the financial backing of this family, he becomes the owner of Samuel de Leeuw cigar factory.

Following the success of this factory, Hendrikus sees his chance in 1917 to acquire a second cigar factory, Van der Mijle, where “Mijlpaaltjes” (milestones) cigars are being produced.

A new era begins for the company as a result of two important decisions. Regional trading activities – buying and selling second-hand cigar machinery – come into effect. To provide the best services for all their clients, Arend’s son, Henk van der Sluis, compiles a team of service technicians to provide maintenance services for cigar machinery.

With cigarette smoking on the rise, the Van der Sluis brothers see new opportunities and set up International Tobacco Machinery to start trading in cigarette machines internationally too.

In 1977, Van der Sluis Cigar Machinery B.V. (SCM) is founded to accommodate international activities relating to the trade in cigar machinery.

Gradually though, more and more production plants are started abroad.

1982, Start up of the production plant in Eindhoven. The site supports rebuilding machines for cigarette production, filter production, and filter cigarette assembly.

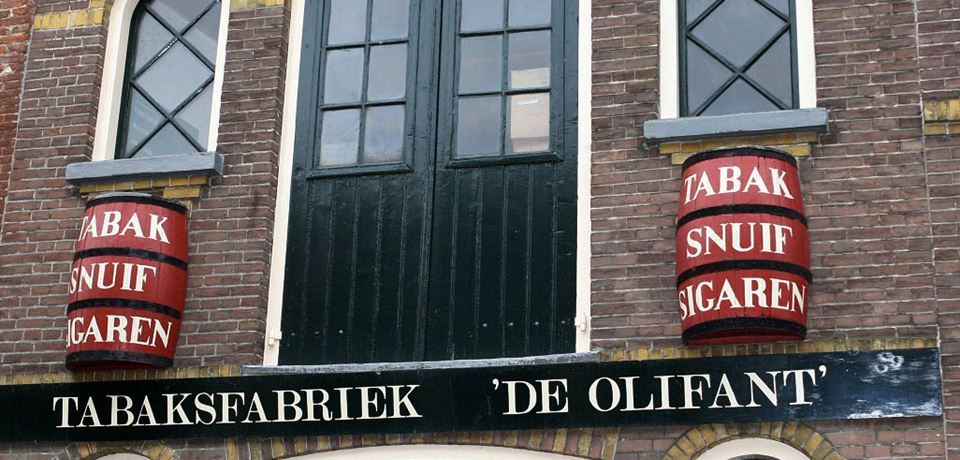

1985, As the last remaining cigar factory, De Olifant, in the historic cigar town of Kampen, is threatened with closure, Henk van der Sluis comes to the rescue to protect the tradition of rolling premium hand-made cigars by buying the complete factory.

By opening production sites and offices abroad, combined with an effective sales network, the company transforms itself increasingly into a truly international enterprise.

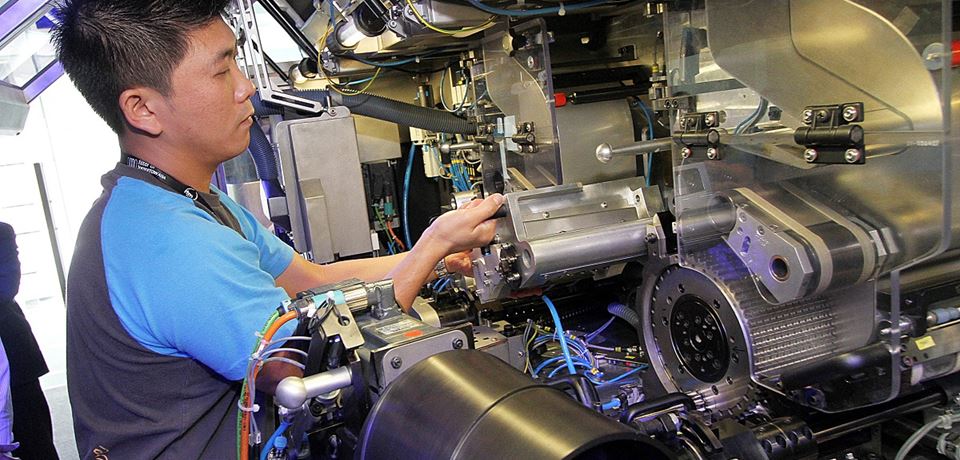

1991, Henk and Arend expand the group by opening an Innovation hub in Poland, with Andrew Stanikowski as director at the helm. This hub is a state-of-the-art facility to drive innovation and accelerate new technologies based on the needs and priorities of the industry.

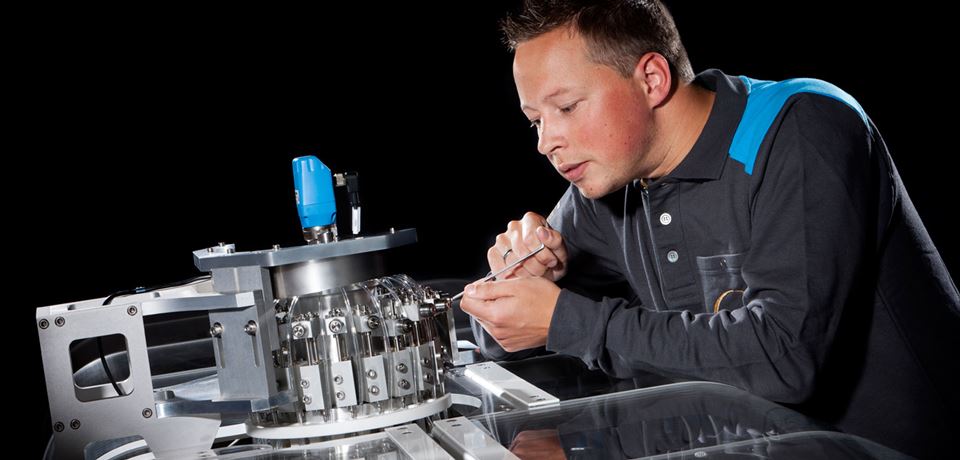

1997, Meeting the need for high-quality OEM components, ITM is now able to produce customized high-quality parts in-house and respond to the market quickly.

1997, To continue new developments in OTP equipment, the Swiss company TDC – in which our current member of the Board, Mr. Jeroen Slobbe (Managing Director of TDC) and Henk van der Sluis (former Managing Director of SCM) were involved – is acquired.

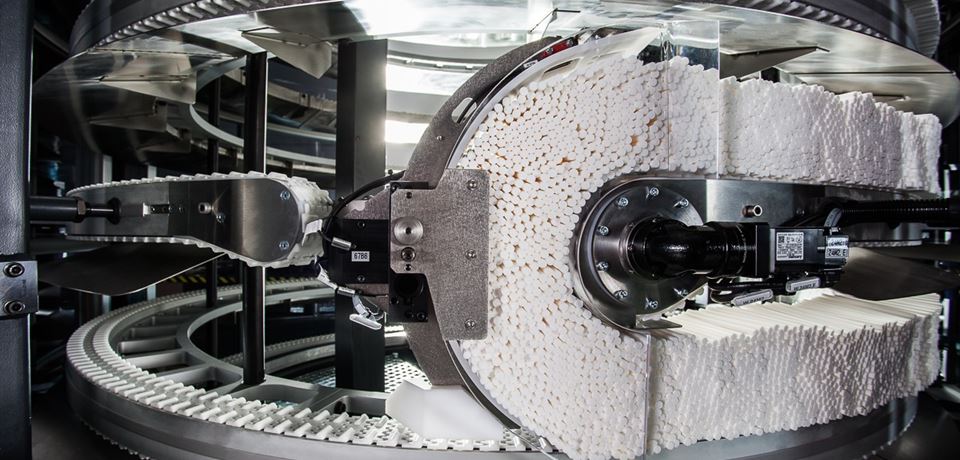

1998, ITM is setting the highest standards by launching Capricorn, the first First-In-First-Out tray buffering technology in the world. This FIFO principle eliminates the drying out and degradation of the products and guarantees curing time while filter rods are transported.

2001, ITM Germany is founded. From this location the company focuses on engineering services, especially developing state of-the-art control systems.

ITM Launches its first recovery platform, Delphi. Tobacco can now be retrieved precisely from all available tobacco products such as cigarettes, cigarillos and cigars, and can be reused easily.

2009, With the launch of the Solaris, a modular multi-segment filter combiner, the clients can easily adjust, handle and produce special filters in a single production cycle.

With the growth of our Service centres, we offer regionally-relevant services. Our SCs are located in every region around the globe to offer access to a rich complement of technology and services and experts who speak the customers’ language and reside in their time zone.

2012, ITM brings the Gemini rod system solution to the market. It is the first tray-based system that can fully operate without needing an operator to be on standby. The automated system eliminates filter mix-ups and misalignments.

ITM introduces a mini reclaiming solution, Delphini, assisting customers with limited space. Because of its small footprint, the reclaimer can be easily integrated with existing equipment.

In 2012, ITM’s Head Office moves from an historic building to new state-of-the-art offices, where it joins its other team members SCM and TDC.

The new headquarters houses the company’s growing team of technology specialists, including developers, quality assurance staff, Sales, Management and other professionals.

2013, ITM strengthens its leader position by acquiring IMAtec, developer of high-speed RYO Booklet machinery. Easy integration with additional modules or packing gives the customer extra flexibility in differentiating their products.

2013, By acquiring Tricas, ITM offers cross-industry experience and material knowledge to help customers increase their new product development capabilities. With technical expertise combined with 3D prototyping of new products, product development goes hand in hand with machine development.

2013, ITM’s logistic family introduces Saturn, a mini FIFO reservoir system specially designed for a small footprint.

2013, With the development of Osiris, ITM completes a turnkey pouch packing line for loose tobacco. Together with the IBIS tobacco weigher, ISIS pouch packer and ANUBIS bundle machine, Osiris forms a flexible, fully integrated and future-proof high-speed packing line that is able to create a variety of packages with one machine.

2013, ITM relocates its cigar rebuilding activities from Kampen to the Dominican Republic, close to its customers. As a subsidiary, GTS/SCM supplies machinery and spare parts to the cigar industry in the Caribbean and Latin America. GTS/SCM holds a vast stock of used cigar machinery.

2014, ITM starts up an e-commerce platform. Customers can order their parts online, not limited to ITM but also for machine parts of other OEMs.

2015, ITM proudly presents Genesis, the first fully automated platform to fill, cap and test e-vaping cartridges. Genesis provides e-vaping producers with a high-volume and highly flexible solution for producing cartridges with smart quality control. In this first year, Genesis is awarded the Golden Leaf award.

2015, Dedicated to constantly improving the customers’ machine technology and its operation, ITM is helping customers with Gemba's Overall Improvement Software (OEE) to identify how to make their businesses operate more efficiently.

2016, the company celebrates its 25th anniversary and demonstrates its total immersion in next generation technology during the ITM Innovation days.

2017, Products like tobacco heating and e-vaping are now of prime importance. To achieve this, ITM will no longer be developing Primary tobacco processing machinery. ITM decreases its development activities in relation to other equipment manufacturers (OEM).

2018, ITM complements its portfolio in pouch-making cigar machinery by acquiring RNT Machinery S.A. in the Dominican Republic. From now on, the company is able to deliver new machinery for cigar packing and drive better solutions for all our customers in Latin America.

2018, ITM Services takes over the portfolio of AccuPac. ITM Services will provide Accupac’s print position technology solutions in wrapping and packing machinery.

2018, ITM UK is closed down, because we are focusing more on innovative machine platforms for producing next generation products.

2018, Andrzej Stanikowski, founder of ITM and PMP Poland, has a street named after him. To commemorate and acknowledge his enormous contribution to the development of the city of Radom and the local community, reflected in the business and social achievements he has inspired. His name is incorporated in our ITM Poland address from now on.

2018, ITM Poland is awarded the Diamond for the Golden Statuette of the Polish Business Leader.

Today, the Van der Sluis family continues to run the company successfully, aiming to achieve goals that are more ambitious than ever.

We love to co-create, discover new markets, use the latest technologies and share expertise – with joy and pride.

We care about creating and maintaining strong, positive relationships with our colleagues, our partners, our customers, and the societies in which we live and work, with respect for diversity.

We are proud to have our roots in the Netherlands, but with more than 1000 of the most talented people, partners, and specialists all over the world, we are excited to help customers create and build amazing things and we've definitely not finished growing yet.

Watch our video to learn more about our story and get in touch to find out how we can help your business. Or if you've been inspired and want to join the ITM Family, visit our Careers page.