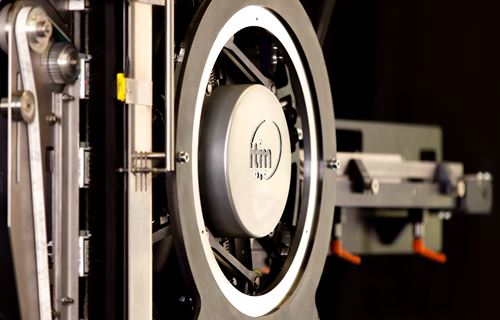

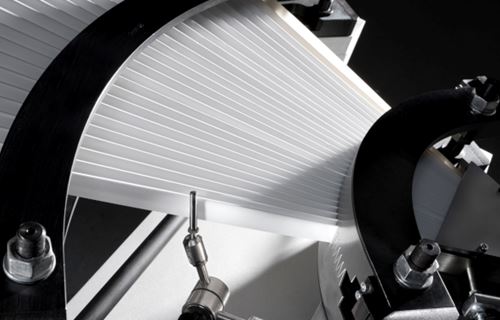

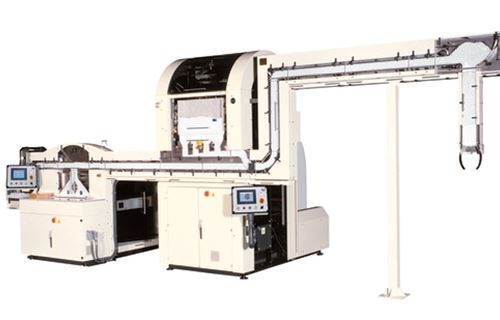

Filter making and combining

ITM has collaborated with the main players in the global tobacco market to develop innovative products for filter making and filter combining, completing the portfolio of filter-related machinery. Today, ITM can deliver full production lines for any type of filter. These production lines include filter making (using acetate or charcoal acetate), filter curing and buffering, filter shooting and multi-segment filter combining, reaching production speeds of up to 500 m/min.

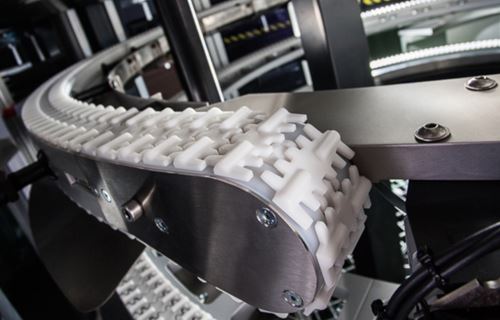

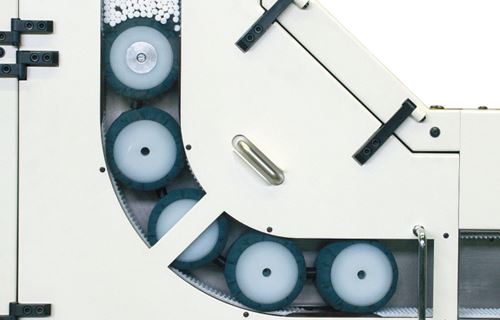

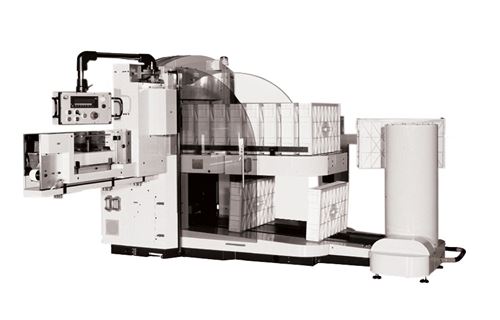

Logistic systems

ITM has a long history in developing logistic systems, such as mass conveyors, tray fillers, tray unloaders and storages. We have designed a unique way of first-in-first-out (FIFO) handling. With the Capricorn we developed the worlds first-in-first-out rod handling system. With continuous monitoring and sampling options, combined with automatic rod rejection, we can guarantee hundred percent quality for all products passing through ITM's logistics systems.

Reclaiming of tobacco

To prevent loss of tobacco, ITM Poland has developed reclaiming platforms, like Delphi and Delphini. These platforms can retrieve tobacco from all available tobacco products, such as cigarettes, cigarillos, cigars and even special-purpose tobacco rods.

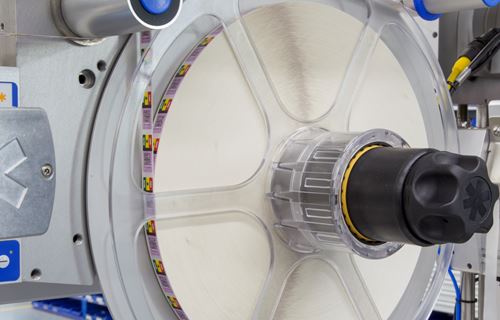

Packing loose tobacco

ITM Kampen (SCM/TDC) offers a full range packing line for loose tobacco, with high dedication to weighing and dosing. In all packing platforms, we pay full attention to flexibility. We are committed to supporting the changes and challenges of our customers, and will provide the best solution for our customers' needs.