The Gemini is a mass flow handling system that uses novel concept of a compartment tray. It gently transports all types of rods including combined filter rods and prevents from rods misaligned. In cooperation with a modular constructed and extendable high bay storage system, Gemini is the first and only industry proven fully automatic filter storage and just-in-time filter distribution system. The complete system can receive, store (cure) and distribute filters with 100% traceability and flexibility, at the highest speed and maximum efficiency without human intervention. The system can also be connected to a local ERP system (Enterprise Resource Planning).

Transferring full and empty sets of trays

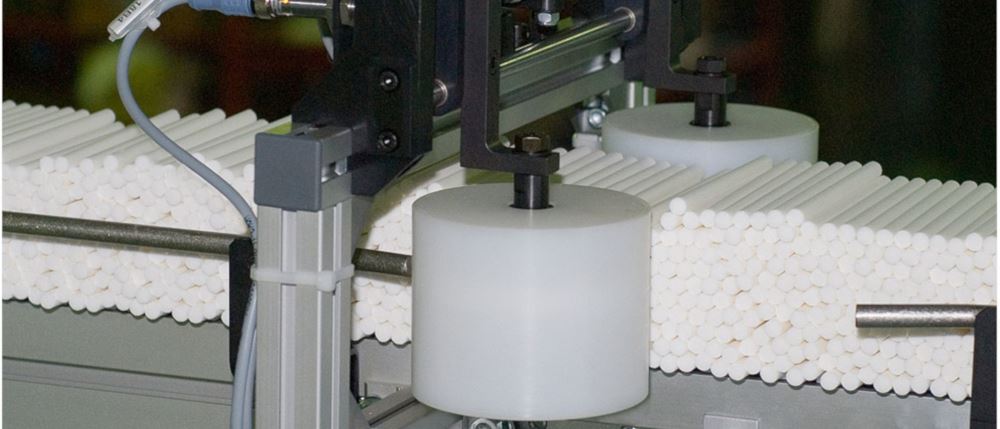

Gemini System includes Tray Filler and Tray Unloader, which are linked with makers and down- stream machines through the mass –flow conveyors. Tray Unloader and Tray Filler can be connected with the high bay storage in order transfer full or empty set of trays.

Gemini uses compartment trays in the handling process. For standardization, only one size of the tray is used for all sizes of filters within the handling range, this feature supports flexibility.